Siemens SIMATIC PCS7 is a comprehensive process control system designed for automation and process management in various industries, such as oil and gas, chemicals, pharmaceuticals, and power generation. It provides a scalable and flexible platform for controlling and monitoring complex industrial processes.

Key features of SIMATIC PCS7 include:

- Engineering: The system offers powerful engineering tools for configuring, programming, and maintaining process automation systems. It includes libraries of preconfigured objects and function blocks, as well as a graphical interface for easy configuration and visualization.

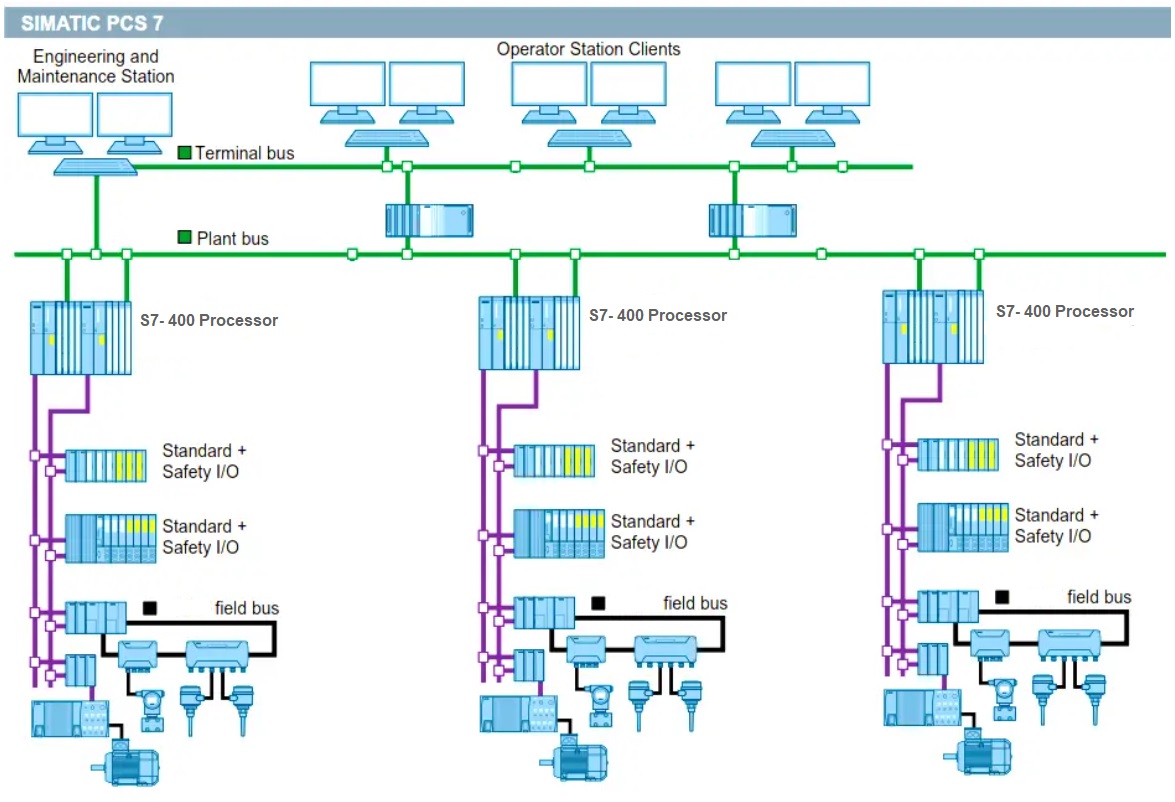

- Distributed Control System (DCS): SIMATIC PCS7 functions as a DCS, allowing for centralized control and monitoring of various field devices, such as sensors, actuators, and controllers. It supports communication protocols like Profibus and Profinet, enabling seamless integration with a wide range of automation components.

- Process Visualization: The system provides a user-friendly interface for operators to monitor and control the industrial processes. It offers graphical representations of the process, including real-time data, trends, and alarms, allowing operators to make informed decisions and respond quickly to any abnormalities.

- Process Control: SIMATIC PCS7 offers advanced control strategies to optimize process performance and ensure safe and efficient operations. It supports various control functions, such as regulatory control, sequential control, and advanced process control (APC), allowing for precise control and automation of complex processes.

- Redundancy and Fault Tolerance: To ensure high availability and reliability, SIMATIC PCS7 offers built-in redundancy features. It allows for redundant controllers, redundant communication networks, and redundant I/O modules, ensuring continuous operation even in the event of a failure.

- Integration with Other Systems: SIMATIC PCS7 can be easily integrated with other systems and applications, such as enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and asset management systems. This enables seamless data exchange and provides a comprehensive view of the entire production process.

- Safety and Security: The system includes comprehensive safety features to protect personnel, equipment, and the environment. It supports safety instrumented systems (SIS) and complies with relevant safety standards. Additionally, SIMATIC PCS7 incorporates robust security measures to protect against unauthorized access and cyber threats.

SIMATIC PCS7 is a widely adopted and well-established process control system used in various industries worldwide. Its modular architecture, flexibility, and powerful engineering tools make it suitable for both small-scale and large-scale industrial applications, providing efficient and reliable process automation and control.